Click the icon to add a specified price to your Dashboard list. This makes it easy to keep track on the prices that matter most to you.

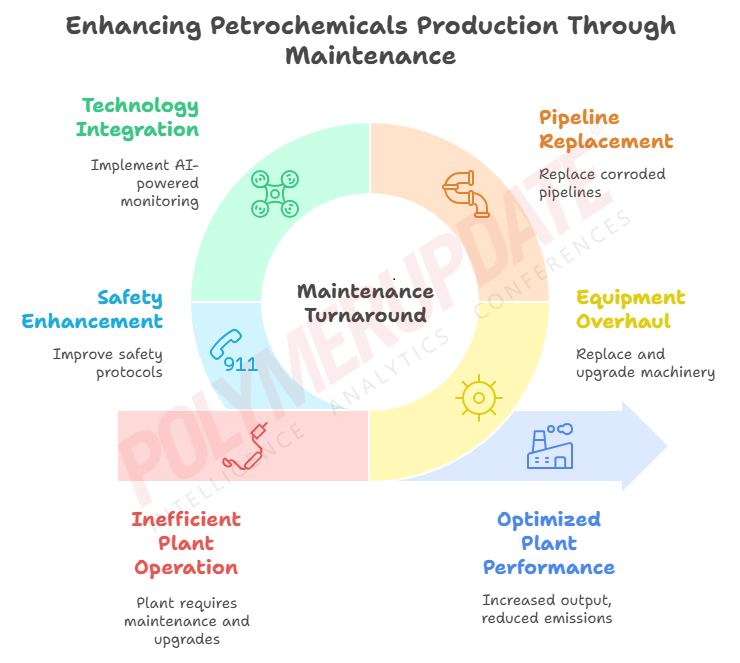

Leading petrochemicals manufacturer Haldia Petrochemicals Ltd (HPL) has announced the completion of its 45-day maintenance turnaround (TA25) at its facility in Haldia, located in the Purba Midnapore district of West Bengal. The company aims to enhance throughput from this plant on a continuous basis, leveraging the maintenance turnaround to meet India’s rapidly growing demand for petrochemicals, driven by rising infrastructure investments.

In a statement, the company said, “The maintenance turnaround began on April 16 and was completed within 45 days, as planned. This initiative was undertaken to achieve operational excellence, technological advancements, and greater sustainability. The turnaround has delivered several benefits for HPL, including improved infrastructure reliability, enhanced safety standards, and a technological framework that supports future growth and innovation. Additionally, process efficiency has improved, fuel consumption has decreased, and carbon dioxide emissions have been reduced.”

Navnit Narayan, Whole-Time Director and Chief Executive Officer (CEO) of Haldia Petrochemicals Ltd, commented, “TA25 exemplifies HPL’s unwavering commitment to safety, innovation, and operational excellence. With the incorporation of digital technologies, we are well-positioned for enhanced productivity and reliable output in the future.” Operational advantages

Operational advantages

HPL, a leading manufacturing venture of The Chatterjee Group (TCG) led by Purnendu Chatterjee, commenced a planned 45-day maintenance and upgradation of its plant on April 16, 2025. This initiative marks a significant step in the company’s pursuit of operational excellence. The TA25 program also underscores technological advancements, consistent throughput enhancement, and a commitment to environmental sustainability.

The turnaround has delivered numerous benefits for HPL, including improved infrastructure reliability, enhanced safety standards, and a technological framework poised for future growth and innovation. Upgrades in equipment and process efficiency are expected to result in increased product output, reduced fuel consumption, and lower CO₂ emissions, aligning with the company’s goals for operational excellence and sustainability. HPL adhered to all statutory requirements for safety inspections and testing, ensuring full compliance and bolstering long-term operational security.

Workers safety

HPL is one of the largest petrochemical companies in India, with a production capacity of 700,000 tonnes per annum (TPA) of ethylene, 491,000 TPA of chemical processing capacity, and approximately 1 million TPA of polymer processing capacity at its manufacturing facility in Haldia. The execution of TA25 was distinguished by meticulous planning and robust safety protocols, involving the deployment of over 11,000 workers during peak times. Comprehensive training initiatives accounted for significant man-hours, ensuring that all personnel were adequately prepared to operate in high-risk environments.

During the TA25 period, the company prioritized the well-being of all participants by providing continuous medical support, access to clean drinking water, ORS supplies, and implementing stringent safety measures. These measures included fire detection systems, gas leak sensors, and strict adherence to personal protective equipment (PPE) standards.

Advanced technologies

The petrochemical manufacturer adopted a ground-breaking approach by integrating advanced technologies into TA25, utilizing AI-powered drone surveillance for real-time monitoring of fire hazards and PPE compliance. These drones, connected to the proprietary JARVIS platform, provided instant alerts and comprehensive analytics, identifying anomalies, potential fire hazards, and PPE violations to significantly enhance safety oversight across the complex.

A robust IT infrastructure was established throughout the facility to support the seamless operation of digital platforms such as the E-Permit system, which enabled real-time job monitoring, interlocking mechanisms, and ensured full compliance with OISD norms. Integrated dashboards for project, safety, and manpower management offered comprehensive visibility into TA25 activities.

Significant upgrades were executed during TA25 to enhance plant reliability and throughput, including: Replacement of major distillation columns and a comprehensive overhaul of all machinery and drivers; Replacement of pipelines affected by corrosion under insulation (CUI); Cracking heater coil replacement, flare tip upgrades, and DCS system enhancements; Cleaning of heat exchangers, overhaul of control valves, and replacement of the gas turbine rotor; Transition from AIS to GIS panels and augmentation of the substation to support the upcoming 345,000 TPA phenol plant; and Implementation of enhanced safety protocols for pressure vessels and safety relief valves.

Investment plan

In March 2025, HPL announced its plans to establish a polycarbonate production plant in West Bengal with a capital expenditure of $1 billion (approximately ₹8,700 crore). The company intends to utilize available land at its existing site in Haldia, marking a significant step toward diversification into the chemical downstream business. Polycarbonate, a thermoplastic compound renowned for its durability against heat, impact, and chemicals, is widely used in industries such as automotive and packaging. Currently, India does not manufacture polycarbonate domestically. Once commercial production begins, polycarbonate will serve as an import substitute. The demand for this material has been steadily rising in India, driven by growth in the automotive and packaging sectors.

At present, India meets its entire polycarbonate demand through imports. According to a company official, polycarbonate production is a logical forward integration of HPL's phenol production, undertaken under a license from Lummus Technology. The basic raw materials for polycarbonate—phenol and acetone—are expected to be produced internally at HPL by mid-2026. This timeline aligns with the completion of HPL’s phenol plant, currently under construction in Haldia, as part of the company’s strategic pivot toward the chemical downstream sector.

DILIP KUMAR JHA

Editor

dilip.jha@polymerupdate.com