Click the icon to add a specified price to your Dashboard list. This makes it easy to keep track on the prices that matter most to you.

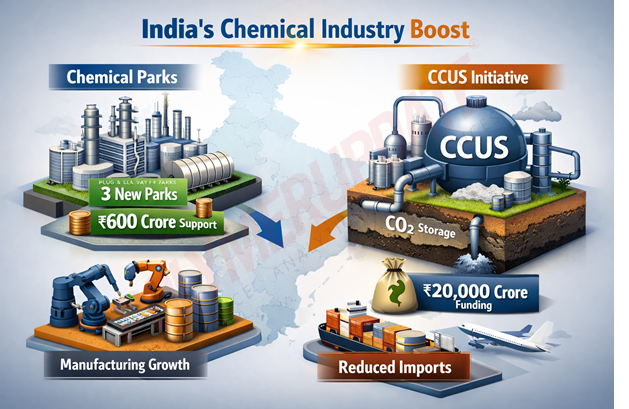

India has announced plans to set up three dedicated chemical parks through a challenge-based route, with a cumulative allocation of Rs 600 crore in the Budget Estimates for financial year 2026–27. The parks will follow a cluster-based, plug-and-play model, featuring shared infrastructure and standard environmental compliance facilities. The initiative aims to strengthen domestic chemical manufacturing, reduce reliance on imports, and enhance global competitiveness. Chemical parks are planned industrial clusters specifically designed for chemical and petrochemical manufacturing, where multiple units operate together while sharing world-class infrastructure and common services. Additionally, an allocation of Rs 20,000 crore has been announced to support the development and deployment of Carbon Capture, Utilisation and Storage (CCUS). This move is intended to ramp up domestic chemical production and reduce dependence on imported products. India ranks as the world’s sixth-largest chemical producer and holds significant potential to further strengthen its presence in global chemical value chains, particularly in higher-value and specialty segments.

Additionally, an allocation of Rs 20,000 crore has been announced to support the development and deployment of Carbon Capture, Utilisation and Storage (CCUS). This move is intended to ramp up domestic chemical production and reduce dependence on imported products. India ranks as the world’s sixth-largest chemical producer and holds significant potential to further strengthen its presence in global chemical value chains, particularly in higher-value and specialty segments.

The chemical sector remains a key driver of industrial growth and exports, supported by established hubs and clusters across Gujarat, Odisha, Andhra Pradesh, and Tamil Nadu, which have attracted investment and generated substantial employment. Building on this foundation, there is a growing opportunity to enhance competitiveness by improving infrastructure integration, streamlining regulatory processes, and strengthening environmental compliance frameworks.

Supply-centric approach

In this context, the Government’s proposal to establish dedicated chemical parks represents a forward-looking, infrastructure-led, supply-side initiative. By offering integrated, plug-and-play (ready-to-use) facilities and coordinated governance, these parks are expected to reduce project timelines and costs, foster cluster-based synergies, and create globally competitive chemical manufacturing ecosystems that support sustainable and inclusive growth.

These parks are envisaged as cluster-based, plug-and-play manufacturing ecosystems supported by common infrastructure and shared facilities. The initiative marks the first instance of dedicated budgetary support for chemical park infrastructure and is intended to strengthen domestic manufacturing capabilities, enhance supply-chain integration, and reduce import dependence in the chemicals sector.

Chemical industry: At a glance

India’s chemical industry is a cornerstone of the manufacturing ecosystem, supplying critical inputs to key sectors such as agriculture, pharmaceuticals, textiles, automobiles, and construction, while contributing about 7 percent to the national gross domestic product (GDP). As the world’s sixth-largest chemical producer and the third-largest in Asia, India manufactures more than 80,000 products spanning bulk and specialty chemicals, agrochemicals, petrochemicals, polymers, and fertilisers.

Within this broad spectrum, specialty chemicals have emerged as a segment of sustained strength, underpinned by India’s process capabilities, cost competitiveness, and growing innovation capacity. Reflecting its structural importance, the Economic Survey 2025–26 notes that the chemical sector accounted for 8.1 percent of manufacturing Gross Value Added (GVA) in FY24, alongside a steady rise in output over the past decade. Production of major chemicals and petrochemicals increased from 45.64 million tonnes in FY16 to 58.62 million tonnes in FY25, translating into a compound annual growth rate (CAGR) of 2.8 percent.

Strategy for chemical parks

The chemical parks are conceived as a comprehensive, infrastructure-led, supply-side initiative to strengthen the foundations of the chemical sector. The major objectives of the chemical parks include enhancing domestic chemical manufacturing capacity, promoting cluster-based industrial development, improving environmental management and safety, boosting the competitiveness of MSMEs, strengthening supply-chain resilience, reducing import dependence, providing plug-and-play infrastructure, attracting domestic and foreign investment, generating employment and supporting skill development, and enabling sustainable and green manufacturing.

India’s chemical industry has already benefited from cluster-based development models such as Plastic Parks, Bulk Drug Parks, and Petroleum, Chemicals and Petrochemicals Investment Regions (PCPIRs), which have demonstrated the advantages of shared infrastructure, anchor investments, and coordinated planning. Building on these successful experiences, the proposed chemical parks are envisioned as an integrated approach encompassing the wider chemical value chain, including bulk, specialty, and downstream segments.

Single location approach

By providing plug-and-play industrial infrastructure, common utilities, logistics support, and streamlined regulatory facilitation within a single location, the initiative is expected to reduce project gestation timelines and capital costs, enable economies of scale and stronger backward and forward integration, improve environmental management and industrial safety through shared facilities, and enhance India’s competitiveness in both domestic and global chemical markets.

Together, the proposed chemical parks and existing cluster-based initiatives—such as Plastic Parks, Bulk Drug Parks, and Petroleum, Chemicals and Petrochemicals Investment Regions (PCPIRs)—establish an integrated policy architecture for cluster-led industrial development in the chemical sector. Backed by targeted policy support and measures to encourage technology adoption, innovation, and sustainability, this integrated approach is expected to deepen domestic manufacturing capabilities and strengthen India’s integration into global chemical value chains over the coming decade.

Schemes for setting up Parks

Plastic Parks have emerged as an integral part of India’s strategy to manage plastic waste, promote recycling, and support the chemical industry. A plastic park is an industrial zone designed specifically for plastic-related businesses and industries. The Department of Chemicals and Petrochemicals formulated the scheme in 2013–14 with the objective of consolidating and synergising the capacities of the plastic processing industry, promoting investment, production, and exports, and generating employment.

To encourage research and development in polymers and plastics, the department has established 13 Centres of Excellence at various national-level institutes. Under the scheme, central grant support of up to 50 percent of the project cost, capped at Rs 40 crore per park, is provided. So far, 10 Plastic Parks have been approved across several states, including Assam, Madhya Pradesh, Odisha, Jharkhand, Tamil Nadu, Uttarakhand, Chhattisgarh, Karnataka, and Uttar Pradesh.

Strengthening environmental management

Green initiatives such as Carbon Capture, Utilisation, and Storage (CCUS), launched in December 2025, play a critical role in reducing industrial carbon emissions by capturing, reusing, or securely storing carbon dioxide before it enters the atmosphere. The Union Budget 2026–27 underscores a strong push to adopt low-carbon technologies in emissions-intensive sectors. An allocation of Rs 20,000 crore has been announced to support the development and deployment of CCUS technologies across key industries, including the chemicals sector, over the next five years.

In this context, integrated chemical parks offer a complementary and enabling platform for translating this climate ambition into practice. Chemical parks aim to provide common environmental infrastructure, shared utilities, and coordinated governance frameworks that are critical to the cost-effective deployment of CCUS and other clean technologies. The clustering of units within a single park enables the implementation of emissions management, waste treatment, and energy-efficiency measures at scale, reducing per-unit costs and improving compliance.

DILIP KUMAR JHA

Editor

dilip.jha@polymerupdate.com