Click the icon to add a specified price to your Dashboard list. This makes it easy to keep track on the prices that matter most to you.

The Bengaluru-based Indian Institute of Science (IISc) has achieved a significant breakthrough in plastic recycling by enhancing the quality of recycled polymers, offering the potential to replace primary materials and make substantial progress toward a circular economy. This revolutionary technology is expected to transform the use of post-consumer plastic waste, leading to better earnings and higher profitability.

A team of researchers has developed a method to improve the quality of recycled plastic, which often deteriorates due to contamination from food and medical waste. The new approach incorporates material from discarded polyethylene terephthalate (PET) bottles, commonly used for water and soda, to enhance the quality of recycled plastics.

According to Prof. Suryasarathi Bose, a Senior Professor in the Polymer Processing Group at the Department of Materials Engineering, IISc, “Post-consumer recycled plastics (PCR) often lose strength and durability compared to virgin plastics due to contamination from food and medical waste during the recycling process. Our goal was to upscale the quality of these PCR plastics for direct use in 3D printing applications.”

| Zero plastic landfill and incineration worldwide by 2050 (%) | ||||

| Calendar year | Incineration/landfill/leakage | Mechanical recycling | Selective solvent dissolution | Chemical recycling |

| 2050 | 0 | 53 | 6 | 41 |

| 2045 | 26 | 44 | 5 | 25 |

| 2040 | 48 | 28 | 3 | 21 |

| 2035 | 62 | 19 | 2 | 17 |

| 2030 | 76 | 14 | 2 | 8 |

| 2025 | 86 | 10 | 1 | 3 |

| 2022 | 88 | 9 | 1 | 2 |

Source: Industry

Note: Figures mentioned in the table rounded off

Present practice

As of today, the physical and chemical properties of post-consumer recycled (PCR) plastics have been enhanced by blending PCR plastics with virgin plastics. “The blend of PCR and virgin plastics contains about 40 percent unused material, which increases carbon dioxide demand, making it difficult to accurately estimate CO2 savings,” Prof. Bose explained.

The new technology breaks down polyethylene terephthalate (PET) plastic into smaller, more useful building blocks. These PET components are then added to recycled polyolefins through a process called melt extrusion, a standard plastic manufacturing method. Previously, the loss of strength and durability in PCR plastics, particularly polyolefins used in packaging and containers, posed a significant challenge. However, the development of this new technology will help address these challenges effectively. Improve versatility

Improve versatility

The key benefit of this material lies in its versatility and resistance to degradation. The newly developed material lasts longer and is less prone to degradation over extended periods. The new technology helps the product remain stronger, more durable, and capable of being reshaped and reused—unlike traditional recycled materials, which often struggle in high-performance applications. Additionally, the newly developed materials may prove to be cost-effective compared to existing plastics in terms of pricing.

Researchers at IISc have partnered with a start-up company, VolLA 3D, to test the material's viability, strength, and durability. Furthermore, the company successfully used a robotic 3D printer to create large, sturdy structures—something previously unachievable with standard recycled plastic. Prof. Bose remarked that this technology, which enables 4D printing using recycled plastics, could be the first of its kind. IISc has replicated the process using discarded milk packets and has also filed for a patent.

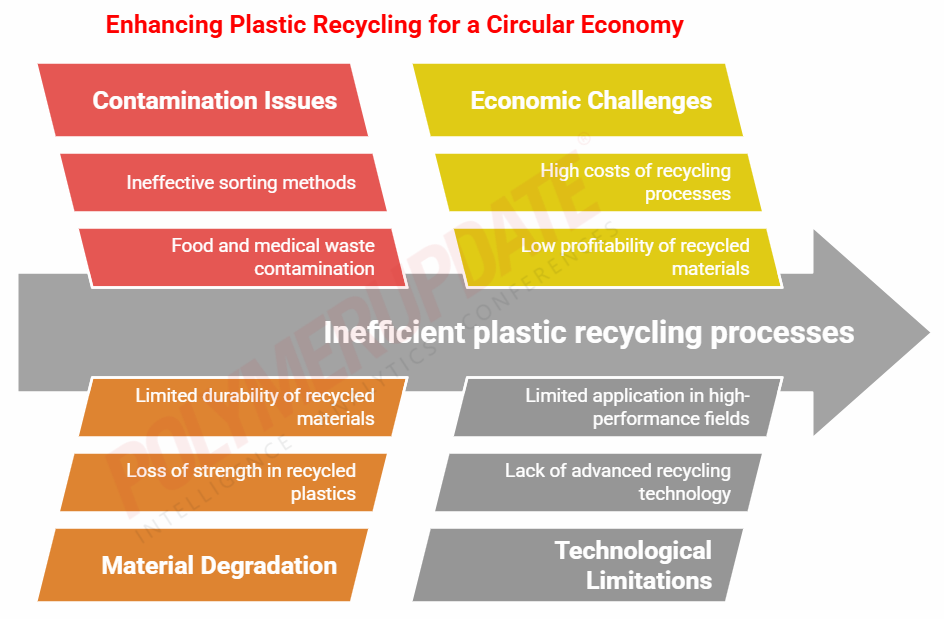

Plastic challenges

Approximately 8 billion tonnes of plastics have been produced since the 1950s, with more than 300 million tonnes now being manufactured annually. Although recycling has been mainstream for decades and mechanical recycling works well for rigid plastics such as polyethylene terephthalate (PET) and mono materials, only about 10 percent of all plastic ever produced has been recycled, at best.

The world faces a steep challenge in the form of an exponentially growing waste ecosystem, which has reached unsustainable levels. This growth is driven by rapid urbanization, economic expansion, increased production, and shifting consumption and expenditure patterns. According to a recent report by the World Economic Forum (WEF) under the Organisation for Economic Co-operation and Development (OECD), inadequacies in waste management planning have led to leakages into terrestrial and marine environments, negatively impacting ecosystems, economies, societies, public health, and food systems.

Plastic waste, in particular, is a significant contributor to the unsustainable surge in waste generation. This is due to its widespread use across industries and the short lifespan of plastic products, including single-use plastics (SUPs), packaging, consumer goods, and clothing. The WEF report estimates that global plastic consumption has quadrupled over the last few decades and that plastic waste is expected to nearly triple by 2060.

Approximately 350 million tonnes of plastic waste are generated worldwide annually, with this figure poised to grow in both scale and complexity. Furthermore, the absence of coherent policy and regulatory frameworks to identify key stakeholders and assign responsibility for managing plastic and municipal solid waste underscores the need for active collaboration across the value chain. Multi-stakeholder partnerships that foster integration, replicability, and scalability of existing waste management initiatives are essential to address this highly complex issue.

Indian scenario

A study conducted by the leading industry body, the All India Plastic Manufacturers’ Association (AIPMA), reveals that India's plastic recycling industry is growing rapidly and is expected to reach US$ 6.9 billion by 2033. “Government initiatives and a strong recycling rate of around 60 percent highlight the nation's commitment to managing plastic waste. Public awareness about environmental issues is also driving this growth. However, approximately 26,000 tonnes of plastic waste per day remain unmanaged due to limited infrastructure and the informal sector's reliance on waste pickers, who require better support,” the study notes.

In alignment with India's Zero Waste goal, efforts are being concentrated on establishing a robust plastic recycling ecosystem. Since the introduction of the Extended Producers’ Responsibility (EPR) Act in 2016, there has been a stronger push for sustainable plastic products and efficient recycling practices. With urbanization, rising incomes, and higher living standards expected to increase plastic demand, the need for ongoing improvements in recycling systems remains critical.

DILIP KUMAR JHA

Editor

dilip.jha@polymerupdate.com